Pultruded Profiles

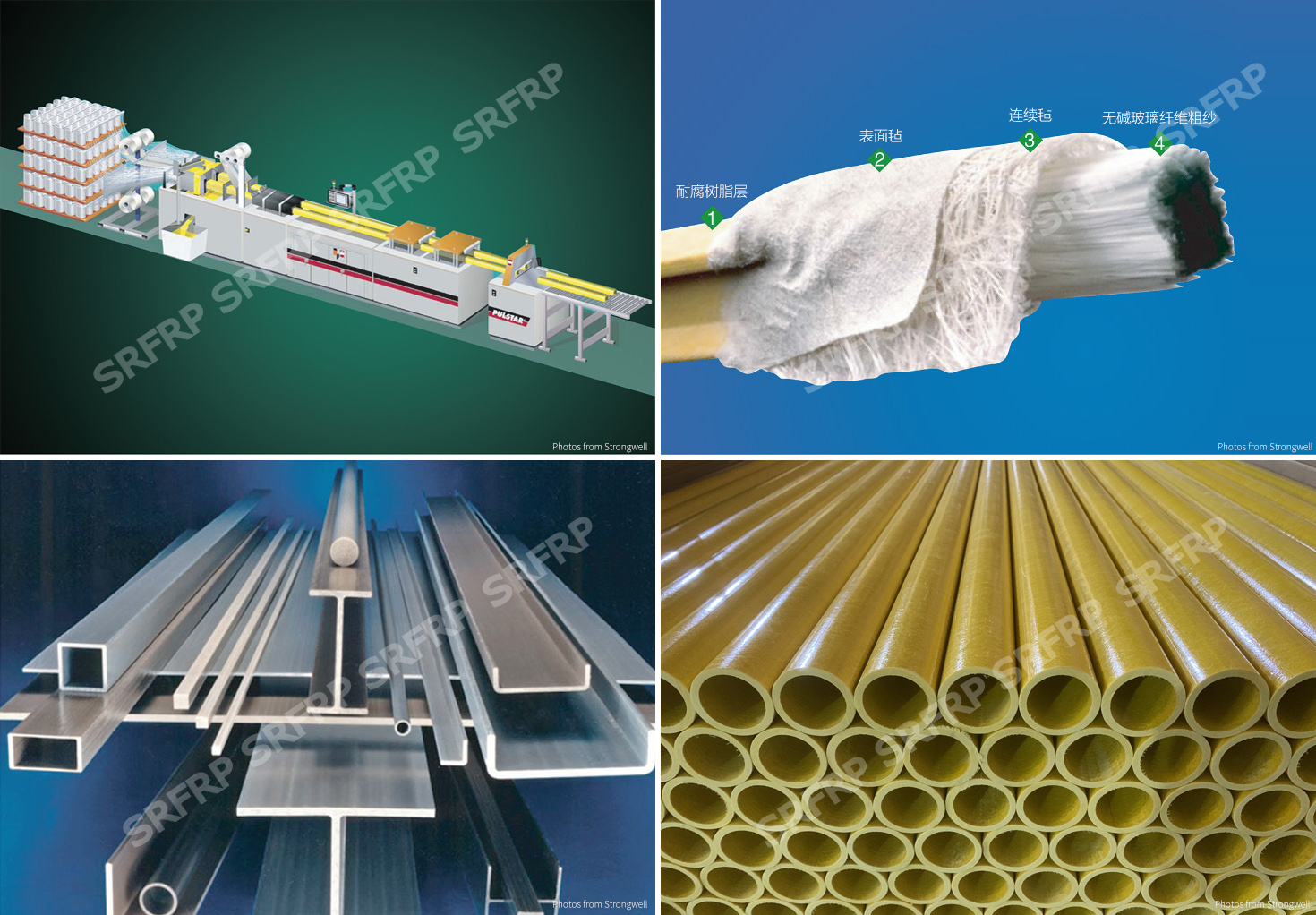

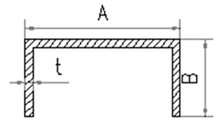

The fiberglass roving, continuous fiberglass blanket and surface felts are fully infiltrated with unsaturated polyester resin, then passed through a certain cross-sectional shape of the mold, under the traction of the pultrusion machine, through heating continuous curing molding, to produce FRP pultruded profiles. The weight ratio of the profile is 35% resin mixture and 65% glass fiber (according to the mechanical requirements, the lay-up design and yarn content can be adjusted), and the pultruded profile of Shirui meets and exceeds the relevant standards of EN13706 E23 or GB/T31539-2015 M23.

We can improve the performance not only by material selection and process design such as lay-up, but also by optimizing the cross-section and structure to meet specific requirements.

We can improve the performance not only by material selection and process design such as lay-up, but also by optimizing the cross-section and structure to meet specific requirements.

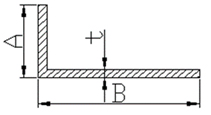

Profiles Specifications

| NO. | Profile type | Size (A×B×t mm) | Theoretical weight (Kg/m) | Figure |

| 1 | I beam | 60×36×5 | 1.33 |

|

| 2 | 76×38×6.35 | 1.6 | ||

| 3 | 100×60×6.5 | 2.48 | ||

| 4 | 150×80×8 | 4.7 | ||

| 5 | 152×76×6.5 | 3.64 | ||

| 6 | 150×150×8 | 7.78 | ||

| 7 | 200×100×10 | 7.42 | ||

| 8 | 200×200×15 | 16.18 | ||

| 9 | 250×152×12 | 10.35 | ||

| 10 | 300×150×15 | 16.5 | ||

| 11 | Channel | 25×20×3 | 0.33 |

|

| 12 | 32×30×3 | 0.42 | ||

| 13 | 44×20×3 | 0.45 | ||

| 14 | 44×60×5 | 1.48 | ||

| 15 | 50×30×5 | 0.98 | ||

| 16 | 54.5×41.5×8 | 2.1 | ||

| 17 | 56×36×5 | 1.03 | ||

| 18 | 70×30×5 | 1.2 | ||

| 19 | 76×25×5 | 1.06 | ||

| 20 | 76×35×5 | 1.32 | ||

| 21 | 80×43×5 | 1.42 | ||

| 22 | 100×44×6 | 2.1 | ||

| 23 | 100×48×6 | 2.22 | ||

| 24 | 120×40×5 | 1.8 | ||

| 25 | 150×50×6 | 2.89 | ||

| 26 | 150×60×9.5 | 4.47 | ||

| 27 | 200×44×8 | 4.13 | ||

| 28 | 200×60×8 | 4.36 | ||

| 29 | 200×80×8 | 6.34 | ||

| 30 | Equal Leg Angle | 35×35×4 | 0.48 |

|

| 31 | 38×38×5 | 0.62 | ||

| 32 | 43×40×5 | 0.7 | ||

| 33 | 50×50×5 | 0.91 | ||

| 34 | 50×50×6.35 | 1.1 | ||

| 35 | 55×55×2 | 0.36 | ||

| 36 | 55×55×3 | 0.58 | ||

| 37 | 50×35×5 | 1 | ||

| 38 | 56×56×4 | 0.8 | ||

| 39 | 60×60×8 | 1.66 | ||

| 40 | 60×48×8 | 1.54 | ||

| 41 | 60×50×8 | 1.56 | ||

| 42 | 76×76×8 | 2.5 | ||

| 43 | 100×40×6 | 1.45 | ||

| 44 | 100×60×6 | 2.8 | ||

| 45 | 100×100×10 | 3.42 | ||

| 46 | L Angle | 25×55×3 | 0.43 |

|

| 47 | 30×70×3 | 0.56 | ||

| 48 | 25×75×3 | 0.58 | ||

| 49 | 25×100×3 | 0.72 | ||

| 50 | 40×300×3 | 2.01 | ||

| 51 | 55×345×3 | 2.32 | ||

| 52 | Square Tube | 32×32×5 | 1 |

|

| 53 | 38×38×5 | 1.11 | ||

| 54 | 40×40×5 | 1.31 | ||

| 55 | 44×44×4 | 1.15 | ||

| 56 | 44×44×5 | |||

| 57 | 44×44×6 | 1.59 | ||

| 58 | 50×50×5 | 1.8 | ||

| 59 | 51×51×6.35 | 2.17 | ||

| 60 | 60×60×5 | 2.1 | ||

| 61 | 60×60×7.5 | 2.85 | ||

| 62 | 63×63×5 | 2.13 | ||

| 63 | 76×76×6.35 | 3.07 | ||

| 64 | 76×76×8 | 4.17 | ||

| 65 | 100×100×6.35 | 4.24 | ||

| 66 | 100×100×8 | 5.4 | ||

| 67 | 125×125×9.5 | 8.33 | ||

| 68 | 130×130×6 | 5.56 | ||

| 69 | Rectangular Tube | 40×20×3 | 0.64 |

|

| 70 | 42×30×2.5 | 0.6 | ||

| 71 | 44×20×3 | 0.66 | ||

| 72 | 60×40×5 | 1.64 | ||

| 73 | 90×63×5 | 3.01 | ||

| 74 | 150×100×8 | 6.95 | ||

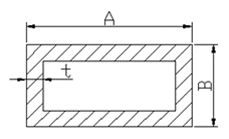

| 75 | Round Tube | 26.5×2.5 | 0.33 |

|

| 76 | 32×2.5 | 0.5 | ||

| 77 | 34×5 | 0.82 | ||

| 78 | 38×3 | 0.58 | ||

| 79 | 38×6.35 | 1.21 | ||

| 80 | 40×4 | 0.88 | ||

| 81 | 50×3.5 | 1.02 | ||

| 82 | 50×5 | 1.33 | ||

| 83 | 75×7.5 | 2.88 | ||

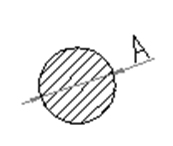

| 84 | Rod | 5 | 0.04 |

|

| 85 | 10 | 0.164 | ||

| 86 | 11 | 0.18 | ||

| 87 | 12 | 0.23 | ||

| 88 | 14 | 0.29 | ||

| 89 | 16 | 0.368 | ||

| 90 | 18 | 0.41 | ||

| 91 | 25 | 0.93 | ||

| 92 | 30 | 1.33 | ||

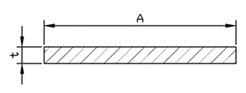

| 93 | Strip/Plate | 20×3 | 0.12 |

|

| 94 | 32×8 | 0.49 | ||

| 95 | 40×25 | 1.89 | ||

| 96 | 50×3 | 0.27 | ||

| 97 | 50×8 | 0.75 | ||

| 98 | 54.5×9.5 | 1.1 | ||

| 99 | 55×12 | 1.26 | ||

| 100 | 80×3 | 0.44 | ||

| 101 | 90×3 | 0.5 | ||

| 102 | 100×3 | 0.53 | ||

| 103 | 100×10 | 1.83 | ||

| 104 | 1000×4 | 7.42 | ||

| 105 | 1030×3.8 | 7.8 | ||

| 106 | 1200×3.3 | 7.75 | ||

| 107 | 1205×5 | 11.07 | ||

| 108 | 1220×3.3 | 8.1 | ||

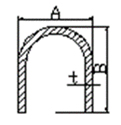

| 109 | Handrail | 60×60×5 | 1.5 |

|

| 110 | 75×63×4 | 1.3 | ||

| 111 | 76×60×5 | 1.5 | ||

| 112 | Kickplate | 104×12×3 | 0.85 |

|

| 113 | 152×13×3 | 1.03 |

|

|

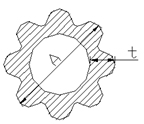

| 114 | Plum Tube | 36×25×5.5 | 0.8 |

|

| 115 | 36×21×7.5 | 1.04 | ||

| 116 | 42×27×7.5 | 1.47 | ||

| 117 | 42×32×5 | 0.97 | ||

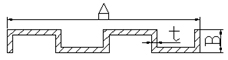

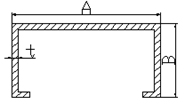

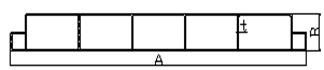

| 118 | Cable Tray | 50×50×3.5 | 1.02 |

|

| 119 | 100×50×4 | 1.18 | ||

| 120 | 100×80×4 | 1.87 | ||

| 121 | 100×100×4 | 2.42 | ||

| 122 | 150×100×3 | 2.24 | ||

| 123 | 200×50×4 | 2.76 | ||

| 124 | 200×100×4 | 3.48 | ||

| 125 | Tray Cover | 57×12×3 | 0.42 |

|

| 126 | 107×12.5×3 | 0.78 | ||

| 127 | 157×14.5×3 | 0.98 | ||

| 128 | 207×15×4 | 1.3 | ||

| 129 | Corrugated Board | 600×20×3 | 3.34 |

|

| 130 | Trapezoid Shape A | 90×40×3.5 | 0.93 |

|

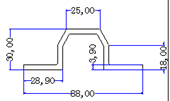

| 131 | Ω shape | 88×30×3.9 | 0.88 |

|

| 132 | Trapezium B | 90×40×3 | 0.85 |

|

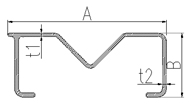

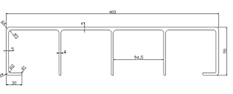

| 133 | M shape | 189×76×5 | 3.21 |

|

| 134 | 189×150×5 | 5.16 | ||

| 135 | Deck | 138×18×3 | 2.2 |

|

| 136 | Trestle Deck | 400×90 | 8.1 |

|

| 137 | Plank | 1000×100×4 | 19.65 |

|

Pultruded profiles technical performance

The dense fiber core layer makes the profile tough and firm, and its absolute values of longitudinal bending strength and impact strength have exceeded those of ordinary steel. The use of glass fiber mat increases the transverse strength of the profile and forms a rich resin layer on the surface, which makes it have good anti-corrosion and anti-rupture characteristics.| Mechanical performance | Unsaturated polyester profiles | Epoxy resin profiles | Polyurethane | Unit | Test Standard | |

| Tensile strength | LW | 394 | 1114.3 | 782 | MPa | GB1447/ASTM D-638 |

| CW | 33.4 | 55.4 | ||||

| Tensile modulus | LW | 24.3 | 48.5 | 55.1 | GPa | GB1447/ASTM D-638 |

| CW | 7 | 12.56 | ||||

| Bending strength | LW | 495 | 1160 | 930 | MPa | GB1449/ASTM D-790 |

| CW | 80 | 314 | ||||

| Bending modulus | LW | 23 | 36 | 44.2 | GPa | GB1449/ASTM D-790 |

| CW | 13 | 20 | ||||

| Compressive strength | LW | 259 | 453.9 | MPa | GB1448/ASTM D-695 | |

| CW | 85.9 | 123.4 | ||||

| Compressive modulus | LW | 20 | 18 | GPa | GB1448/ASTM D-695 | |

| CW | 7 | 10 | ||||

| Interlaminar shear strength | 29.1 | 37.3 | 22.5 | MPa | GB 3357/ASTM D-2344 | |

| Impact toughness | 220 | 477 | 397 | KJ/m2 | GB 1451/ASTM D-256 | |

| Physical properties | Unsaturated polyester profiles | Epoxy resin profiles | Polyurethane | Unit | Test Standard | |

| Barcol Hardness | 50 | —— | GB 3854/ASTM D-495 | |||

| Water absorption (25℃,24h) | 0.06 | % | GB 1462/ASTM D-570 | |||

| Density | 1.8 | 2.17 | g/cm3 | GB 1463/ASTM D-792 | ||

| Coefficient of thermal expansion (LW) | 37 | 10-6/℃ | GB 2572/ASTM D-696 | |||

| Thermal conductivity | 0.08 | W/(m.K) | GB 3139/ASTM C-518 | |||

| Electrical Properties | Unsaturated polyester profiles | Epoxy resin profiles | Polyurethane | Unit | Test Standard | |

| Arc resistance (LW) | 182 | 181 | seconds | IEC 61621:1997 | ||

| Dielectric strength (PF) | 9.93 | KV/mm | GB 1408/ASTM D-149 | |||

| Dielectric constant (PF) | 4.19 | @60hz | GB 1409/ASTM D-150 | |||

| Dye penetration test | 15min Not penetrated | 15min Not penetrated | —— | DL/T 1580-2016 | ||

| Surface resistance coefficient | 3.51*1012 | 7.2*1013 | 2*101515 | Ω | GB 1410/ASTM D257 | |

| Volume resistance coefficient | 3.6*1014 | 1.5*1014 | 5.6*1013 | Ω.cm | GB 1410/ASTM D257 | |

| Fire retardant properties | Unsaturated polyester profiles | Epoxy resin profiles | Polyurethane | Unit | Test Standard | |

| Flame propagation rate | 15 | —— | ASTM E84 | |||

| Flammability (vertical method) | V-0 | V-0 | Level | UL 94-2013 | ||

| Oxygen index | 32 | 30 | % | GB 8924/ANSI UL-94 | ||

FRP pultruded profile is a structural member with the advantages of light weight and high strength, corrosion resistance, insulation and non-magnetic.

FRP pultruded profiles also have good designability. Various profiles can be made into various products through proper connection and combination, such as: structural platform, frame beam, bracket, fence, inclined ladder, straight ladder, guardrail, etc., which are widely used in different fields.

FRP pultruded profiles also have good designability. Various profiles can be made into various products through proper connection and combination, such as: structural platform, frame beam, bracket, fence, inclined ladder, straight ladder, guardrail, etc., which are widely used in different fields.

EngLish

EngLish  简体中文

简体中文 Pусский

Pусский بالعربية

بالعربية Deutsch

Deutsch Français

Français 日本語

日本語

Products

Products Email

Email Phone

Phone